Real-time machinery analytics solution that continuously monitors asset and process health, enabling industrial facilities to predict and prevent asset failures, improve operational performance, and manage reliability and maintenance efficiently.

Asset performance management

My role

Design a vision direction for the solution that can highlight opportunity areas and start conversations around modernization of the interfaces from the dated legacy tools that users use to manage assets currently.

The team

1 designer ('tis I ), 3 Developers, 1 Product managers.

Duration

1 month

Outcome

Designed a vision story for curated set of issues which were positively received by SMEs and the team. This kick started the modernization of UI within Honeywell APM products

User roles, jobs and issues

Users and jobs involved in managing assets in oil and gas plants

Rashid Ahmed

Maintenance

Engineer

-

Monitor Asset Health

-

Execute Proactive Maintenance Actions

-

Improve Plant Health, Performance & Efficiency

Petra Ramirez

Maintenance

Technician

-

Execute day to day inspections & work orders

-

Capture observation details & updates to supervisor

-

Accurate information collation for evidence

Carrie Fisher

Reliability

Engineer

-

Monitor the Reliability KPIs

-

Ensure Reliability KPIs are within limit

-

Analyse root causes for frequently occurring faults

Problems with current tools

No RBAC - One size fits all,

no customisation capability

No Search - Complex navigation experience

Workflow divided across

multiple apps

Desktop only and does not consider on the go scenarios

UX opportunities

Mobile first workflow

Insights driven actions

Search first navigation

STORY 1

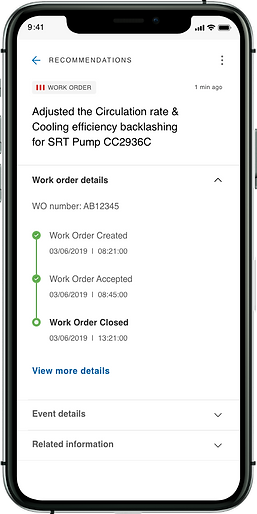

Tackling an issue on the go

Rashid (Maintenance engineer) On the field on a morning site visit. Gets notified on his mobile about an issue in one of the assets.

He opens the notification to inspect

01

He learns about the issue with the asset.

02

He wants to identify the exact issue and the KPI impacted

03

He then decides to create a Work order to inspect

04

He assigns it to 'Petra' (maintenance technician)

05

Petra Ramirez (Maintenance Technician) on the field gets notified on her mobile about the work order that is assigned to her.

06

She opens the notification and inspects it.

07

Just like Rashid she has access to the asset analytics but in a limited scope

08

She starts the work order and completes the steps specified by the system with contextual assistance through out the process

07

She finished the order and marks it as closed

08

Rashid (Maintenance engineer) can always track the status on this mobile as well as get updates on the progress.

09

10

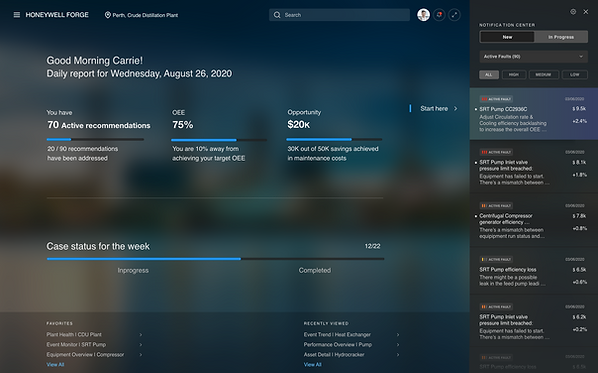

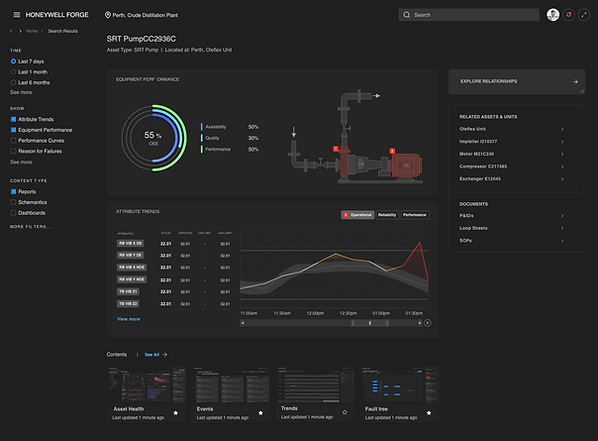

STORY 2

Locating the right information at right time

Carrie (Reliability engineer) at the control room. wants to identify the low performing pumps in one of the units. She does not know where to look for exactly but she needs a way to start scoping down.

01

As she logs in to APM she gets a summary of the overall KPIs of the as well as some high priority issues if any.

02

She does a quick search on the header for 'low performing pumps' in plain language using a NLP based search capability

03

She gets a list of results that match the query along with additional insights

04

She then identifies the pump that has the least performance and learns more about the attribute details of it.

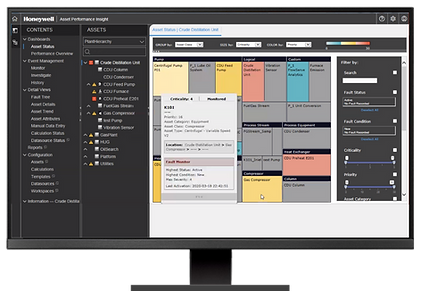

STORY 3

Flexibility in using the system

Rashid (Maintenance engineer) is away in a site. He wants to understand how different units in the plant are working. He knows the plant like the back of his hand but there are thousands of assets and it gets difficult to identify where the issues can arrise from.

01

He logs in to APM and navigates to the plant status page and switches to the map view he is most familiar and comfortable with

02

He immediately locates an area in the plant where there are under operating assets and pinpoints the pump that has a potential fault identified

03

He wants to learn about the root case of the fault for which he navigates into the pump detail page where he can find the issues and later decide to take a corrective action or assign an inspection order.

Impact

This effort had led to other product areas exploring and reimagining the products with modernised components and demystifying the perceived complexity into simple user jobs and motivations.

Asset performance management solutions has defined a modernisation roadmap and incorporated the UI and UX pattern enhancements in a phased manner